How Gas-Powered Log Splitters Work: Key Components and Advantages

The mechanics of a gas-powered log splitter operation

Log splitters that run on gas typically work by having their combustion engine power a hydraulic pump. This creates lots of pressure inside the system, forcing hydraulic fluid into a cylinder. When this happens, a steel ram gets pushed outwards, slamming logs against a fixed wedge with around 34 tons of splitting force behind it. The whole process works pretty well time after time. Engine runs pump, pump builds pressure, pressure moves ram forward - this delivers serious muscle to tackle even tough hardwoods. Because of how much power these machines pack, they're really good at handling big diameter logs when someone needs to split wood continuously throughout the day for heavy duty tasks.

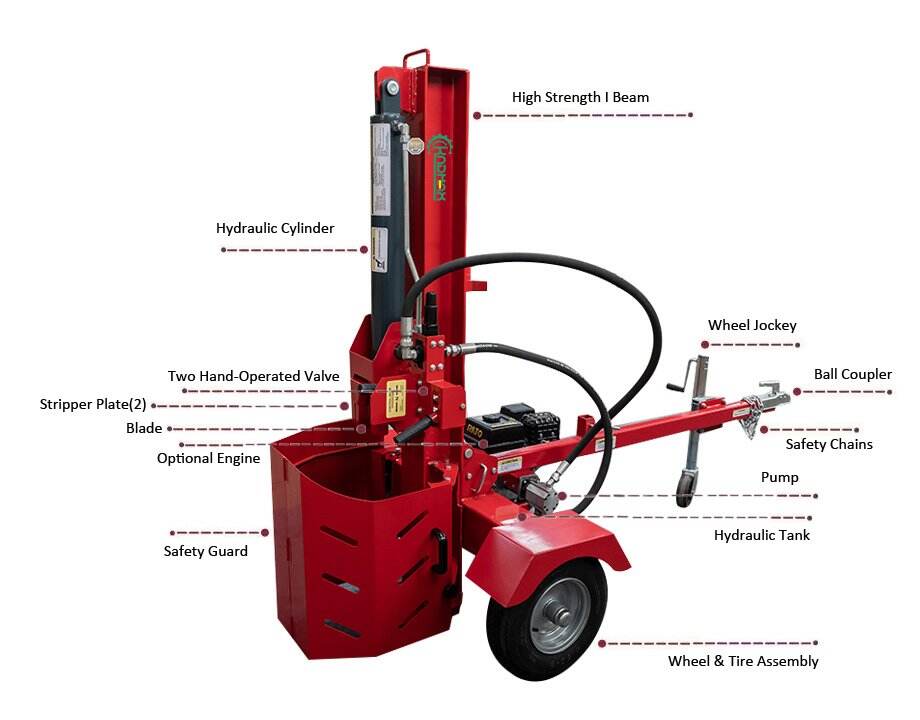

Key components: hydraulic system, ram, wedge, and engine

There are basically four main parts that need to work together for good performance. Most residential models come with a small gas engine, usually around 5 to 10 horsepower, which drives the hydraulic pump responsible for building pressure in AW32 hydraulic oil. Once pressurized, this oil moves through heavy duty hoses until it reaches the hydraulic cylinder where it gets converted into straight line movement that extends the hardened steel ram outwards. When operating, the ram actually forces the log against a specially treated steel wedge designed to focus all that power right where it needs to go to break apart those tough wood fibers. Regular maintenance following what the manufacturer recommends is absolutely essential if operators want their equipment to last and perform at its best over time.

Gasoline vs. electric log splitters: Which is right for your needs?

The decision between gas and electric log splitters really comes down to what kind of work needs doing and where it's happening. Gas splitters pack quite a punch when it comes to mobility and raw power, putting out anywhere from 8 to 34 tons of splitting force without needing access to electricity. That makes them great choices for folks working in remote areas or dealing with serious splitting jobs. But there are downsides too. These machines need regular maintenance checks, spew exhaust into the air, and their noise level can be pretty annoying compared to electric versions. Electric splitters run much quieter, don't pollute the air, and generally need less upkeep. They work fine for people who only split wood now and then or deal with small pieces. Most backyard owners who just cut up a few cords each year will find electric models perfectly adequate. But anyone tackling massive quantities of wood or stubborn hardwood species would probably want to invest in a gas model instead.

Pre-Use Inspection and Safe Setup of Your Log Splitter

Conducting a thorough pre-use inspection of the log splitter

Before each use, perform a quick but thorough inspection to identify potential hazards. Check for visible damage, wear, or leaks across all components. Ensuring everything is in working order takes only minutes but greatly reduces the risk of malfunctions or accidents during operation.

Checking fluid levels, hoses, and structural integrity

Make sure the hydraulic fluid is at proper levels using whatever the manufacturer recommends, usually something like AW32 hydraulic oil, and add more if necessary. Gas powered machines need special attention too — don't forget to look at both engine oil and fuel levels prior to startup. Take a good look at those hydraulic hoses. Any bulging, cracking, or worn spots might mean trouble down the road when pressure builds up. And while we're talking about safety, give the machine frame a thorough inspection. Bends, cracks, or signs of metal fatigue anywhere along the structure aren't just cosmetic issues. They can seriously impact how safe and reliable the equipment remains during operation.

Setting up a safe work area: Clear debris, level ground, and proper lighting

Always find somewhere level and solid to place the equipment, not near hills or bumpy ground. Clear away anything that might cause someone to trip like stones, sticks or other debris around where it will sit. When working in dim light situations, make sure there's enough illumination so everyone can see what they're doing. Most professionals suggest keeping people and animals at least ten feet back from the machinery while it runs. This buffer zone helps prevent accidents when things get moving.

Stabilizing the machine: Locking wheels and preventing movement

Lock down those wheels and extend the stabilizers so nothing moves around while working. For anyone pulling a towable unit, remember to disconnect completely and park it on solid ground first. Give various spots a gentle push to check if everything holds steady the whole time. When things are properly secured, we avoid dangerous tipping incidents and keep our splits going straight without wandering off track. A little extra effort here goes a long way toward safety and getting clean results every time.

Essential Safety Gear and Personal Protective Equipment (PPE)

Must-have PPE: Safety glasses, gloves, steel-toed boots, and hearing protection

When running a gas log splitter, proper gear isn't optional it's mandatory. Safety glasses rated by ANSI standards keep wood chips and splinters from getting into eyes during operation. Thick gloves made for cutting tasks help handle logs safely without slipping, while steel toe footwear protects feet from potential drops or kicks. Don't forget ear protection either those loud engines regularly hit noise levels above what's considered safe for long periods according to workplace safety guidelines from 2023. Without this basic kit, operators risk serious injury from all sorts of accidents that happen faster than expected around heavy machinery.

What not to wear: Avoiding loose clothing and jewelry

Loose clothes, drawstrings, long sleeves, or flashy jewelry are all hazards when working around moving equipment. The Occupational Safety and Health Administration reports that getting tangled in machinery causes thousands of serious injuries each year on job sites across the country. Workers should stick to snug fitting uniforms made for the job and take off anything that might snag - think wedding bands, wristwatches, even those trendy pendant necklaces. Taking just a minute to check what's worn can make a world of difference in preventing accidents where body parts get trapped between components or pulled into rotating parts. Common sense really does go a long way in keeping workplaces safe.

Safe Operation: Step-by-Step Guide to Using a Gasoline Log Splitter

Reading the operator's manual and understanding controls

Begin every new experience with your log splitter by reading the operator's manual thoroughly. It contains model-specific details about controls, safety features, and proper procedures. Understanding this information helps prevent misuse and ensures you operate the machine safely and effectively.

Starting and stopping the engine safely

Before starting things up, take a moment to check both fuel and oil levels. Use proper containers designed for this purpose and work in an area where air can circulate freely. Each manufacturer has their own specific way of getting the engine ready - some need priming, others require adjusting the choke, and most will need a good pull start. Safety first folks! Don't ever try to fill up fuel when the engine is still warm or running. Let it cool down properly first. And when wrapping things up at the end of the day, remember to release all those control levers, give the engine a short idle period, and then shut it off completely. This helps balance out all those internal pressures inside the machine.

Proper body positioning: Standing to the side and avoiding hand contact

Standing off to the side of the machine instead of right in front keeps operators safe from the ram movement and possible kickbacks that can happen unexpectedly. Hands and feet need to stay well away from where the split actually occurs during operation. When positioning logs, always grab some sort of tool like tongs rather than reaching in with bare hands while the equipment remains active or pressurized. A good footing makes all the difference too. Feet placed roughly as wide as shoulders provides better balance when working around heavy machinery, reducing the risk of losing control during critical moments.

Using two-hand controls and avoiding distractions during operation

Use the two-hand control system as designed it keeps both hands away from the danger zone during activation. Stay focused: avoid conversations, phone use, or other distractions. Before each session, test the emergency stop function to confirm it operates correctly. Full attention minimizes reaction time in unexpected situations.

Maintaining Safety Zones and Preventing Common Log Splitter Accidents

Understanding Operator Zones and Maintaining Safe Distances

Keep at least ten feet away from the log splitter when operating it. This buffer zone helps prevent injuries from flying wood chips, unexpected splits, or if the machine shifts during operation. Stand off to one side instead of directly facing the splitting action. The angle gives better visibility while keeping body parts clear of where most accidents happen. Wood doesn't always behave as expected when split under pressure. Staying back isn't just about avoiding broken equipment either. There are plenty of other risks that come with being too close when things go wrong, some of which aren't immediately obvious until it's too late.

Leveraging Built-In Safety Features: Shields, Automatic Shut-Offs, and Emergency Stops

Gas log splitters today come equipped with several built-in safety features designed to keep operators safe. Most units have two hand controls so fingers stay away from moving parts when the machine is running. There are also protective covers that catch flying debris and chunks of wood, plus red emergency stop buttons right where they can be reached quickly if something goes wrong. Better yet, newer models often include automatic shut off mechanisms that kick in whenever there's unusual pressure buildup or unexpected movement detected. According to industry safety data, folks who actually follow all these safety protocols might avoid around seven out of ten injuries related to log splitting each year.

Recognizing and Avoiding High-Risk Behaviors During Use

The majority of incidents happen because people take unnecessary risks rather than due to faulty equipment. Don't try adjusting settings, taking measurements, or clearing jams while machinery is still running or pressurized. Operators should stay away from using the splitter altogether when feeling exhausted, mentally scattered, or rushing against deadlines. Trying to force logs into position by hand ranks among the worst things anyone can do around such equipment. The hydraulic system exists precisely for situations like this, so let it handle what it was designed for. Getting rid of these bad habits doesn't just prevent injuries but actually makes operations run smoother day after day.

FAQs

What are the advantages of a gas-powered log splitter over an electric one?

Gas-powered log splitters offer greater mobility and raw power compared to electric splitters. They can deliver anywhere from 8 to 34 tons of splitting force and do not require access to electricity, making them ideal for remote areas or heavy-duty tasks.

Why is regular maintenance important for gas log splitters?

Regular maintenance ensures optimal performance and longevity of the machine. It helps identify potential hazards such as leaks or worn-out parts that might lead to malfunctions or accidents during operation.

What safety measures should be taken before operating a gas log splitter?

Before operation, conduct a thorough inspection for any damage or leaks, check fluid levels, and ensure all components are secure. Set up the machine on level ground, clear any debris, and ensure proper lighting in the work area.

Table of Contents

- How Gas-Powered Log Splitters Work: Key Components and Advantages

- Pre-Use Inspection and Safe Setup of Your Log Splitter

- Essential Safety Gear and Personal Protective Equipment (PPE)

- Safe Operation: Step-by-Step Guide to Using a Gasoline Log Splitter

- Maintaining Safety Zones and Preventing Common Log Splitter Accidents

- FAQs