Daily Cleaning Protocols for Chipper Shredders

Structured daily cleaning routines extend equipment lifespan by up to 40% while reducing failure rates. Focus on debris mitigation, component integrity, and corrosion prevention.

Post-Operation Debris Removal

After shutdown, disconnect the spark plug wire and clear residual material from cutting chambers with stiff-bristle brushes or compressed air. Target blade housings where wood sap accumulates, compromising efficiency. Avoid pressurized water near engine components. For sticky residues, use plant-based degreasers before mechanical removal.

Critical Component Inspection

Check daily:

- Blade Integrity: Nicks, warping, or lodged objects

- Bolt Tightness: Especially drive-belt covers

- Bearing Seals: Sawdust infiltration indicates failure

- Electrical Connections: Fray-free wiring and secure terminals

Preventing Buildup in Discharge Chutes

Clear obstructions with flexible rods after each batch. For persistent clogs, disassemble removable sections and wipe with dry microfiber cloths. Quarterly anti-static coatings reduce particulate adhesion by 60%.

Moisture Control for Rust Prevention

Wipe external surfaces with silicone-treated cloths and use moisture-absorbing packets near bearings. For overnight storage, use breathable canvas covers over intake points. In humid environments (>70% RH), run the engine briefly post-cleaning to evaporate moisture.

Blade Maintenance Systems for Chipper Shredders

Diagnosing Blade Dullness and Damage

Inspect for edge rounding (>2mm radius), micro-fractures, or deformation. Blades requiring excessive force or producing uneven chips indicate dullness. Early detection prevents collateral damage.

Professional Sharpening Methodology

Restore blades with specialized grinding at 30–35° bevel angles. Coolant-controlled processes prevent overheating and maintain steel tempering. Avoid manual filing to prevent uneven edges.

Replacement Timing and Alignment

Replace blades when edges lose over 25% of material depth or have irreparable chips. Install new blades with torque calibration and verify <0.005" axial runout to prevent imbalance.

Corrosion Resistance for Extended Lifespan

Apply thin-film protectants with rust inhibitors after cleaning. Consider corrosion-resistant alloys like boron steel for harsh environments. Store blades in low-oxygen containers off-season.

Lubrication Management in Chipper Shredders

Proper lubrication reduces friction-related failures by 53% and extends service cycles.

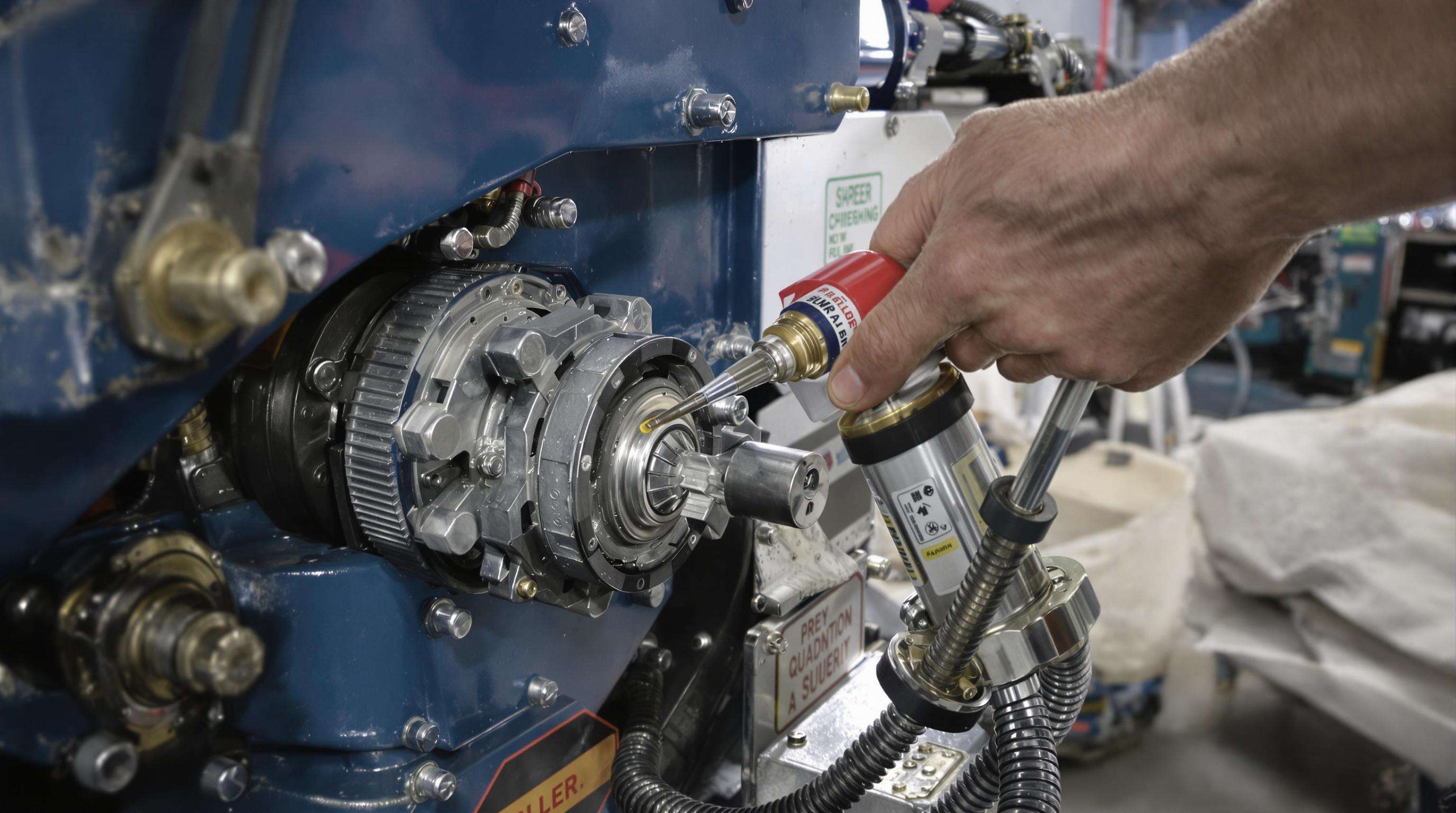

Bearing and Joint Greasing Cycles

Grease pivot joints every 4-5 operating hours, focusing on rotor shafts and hopper hinges. Wipe residual debris before reapplying. Inspect quarterly for early wear.

Hydraulic System Fluid Maintenance

Monitor reservoirs monthly for discoloration or viscosity changes. Replace fluids annually or after 400 hours in dusty environments. Flush systems when switching types.

Lubricant Selection for Extreme Conditions

Use temperature-resilient synthetics in freezing or high heat. Choose marine-grade formulations for humidity and lithium-complex greases for heavy debris. Avoid multipurpose products below -20°F.

Engine Care for Chipper Shredder Longevity

Air Filter Maintenance

Inspect air filters every 20 hours. Clean reusable filters with compressed air or replace torn/dirty paper filters. Clogged filters increase fuel consumption by 10%.

Oil Change Intervals and Viscosity

Change oil after the first 5 break-in hours, then every 50 hours or seasonally. Use manufacturer-specified viscosity (typically SAE 30). Warm the engine before draining.

Fuel System Winterization

For storage exceeding 30 days:

- Add stabilizer to fresh fuel and run briefly

- Drain carburetor bowl

- Remove spark plugs and inject fogging oil

- Seal air intake

Seasonal Storage Protocols for Chipper Shredders

Pre-Storage Cleaning and Lubrication

Remove all organic debris and lubricate pivot points. Drain or stabilize fuel to prevent carburetor varnish. Use ethanol-free options when possible.

Climate-Controlled Storage Solutions

Store in 40-60°F (4-15°C) with <50% humidity. Elevate outdoor units on pallets and use breathable covers. Store batteries separately in climate-controlled spaces.

Spring Reconditioning Steps

Inspect for damage and test battery voltage. Replace stabilized fuel and check oil levels. Conduct a no-load startup and verify smooth operation.

Operational Safety Procedures for Chipper Shredders

Pre-Start Inspection Requirements

Check safety guards, emergency stop mechanisms, and hydraulic lines. Inspect blades for foreign objects.

Lockout Protocols During Maintenance

Shut off power and remove spark plug wires. Use physical locks and tags. Verify zero energy state before servicing.

Maintenance Scheduling for Chipper Shredders

Blade Sharpening Frequency Planning

Residential use: Sharpen every 5-10 hours. Commercial use: Every 2-4 hours. Schedule preemptive sharpening for seasonal peaks. Annual professional inspections detect microfractures.

FAQ

What are the key steps for daily cleaning of chipper shredders?

Daily cleaning involves debris removal from cutting chambers, checking critical components such as blade integrity and bolt tightness, and clearing clogs in discharge chutes while ensuring moisture control to prevent rust.

How often should chipper shredder blades be inspected and sharpened?

Blades should be inspected for dullness and damage regularly, typically sharpening every 5-10 hours for residential use and every 2-4 hours for commercial use.

What is recommended for lubricant management in chipper shredders?

Lubricate pivot joints every 4-5 operational hours, monitor hydraulic fluids monthly, and choose the right lubricant for extreme conditions.

How should the engine be maintained for longevity?

Regular checks of air filters and timely oil changes are crucial. Winterize the fuel system for long storage periods by adding stabilizer and draining the carburetor.

What are effective seasonal storage protocols for chipper shredders?

Effective storage includes pre-storage cleaning, climate-controlled storage, and proper reconditioning steps in spring.

Table of Contents

- Daily Cleaning Protocols for Chipper Shredders

- Blade Maintenance Systems for Chipper Shredders

- Lubrication Management in Chipper Shredders

- Engine Care for Chipper Shredder Longevity

- Seasonal Storage Protocols for Chipper Shredders

- Operational Safety Procedures for Chipper Shredders

- Maintenance Scheduling for Chipper Shredders

-

FAQ

- What are the key steps for daily cleaning of chipper shredders?

- How often should chipper shredder blades be inspected and sharpened?

- What is recommended for lubricant management in chipper shredders?

- How should the engine be maintained for longevity?

- What are effective seasonal storage protocols for chipper shredders?